Double Sided PCB: A Versatile Solution Double Sided PCB for Advanced Electronics

Introduction:

In the ever-evolving world of electronics, the demand for smaller, efficient and reliable circuit boards continues to grow. One such essential component is the Double Sided PCB (Printed Circuit Board). In this article, we will explore the manufacturing process, characteristics, advantages, usage methods, tips for selecting this product and conclude with its significance in the electronic industry.

Manufacturing Process:

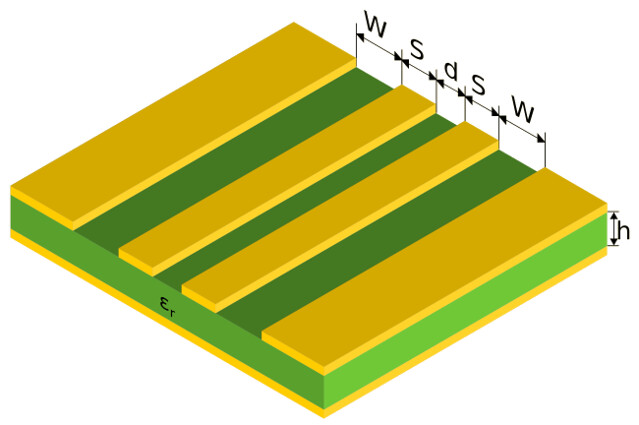

The Double Sided PCB is designed using a sandwich circuit board structure. It consists of two copper lay Double Sided PCB ers with insulating material in between. The top layer acts as one conductor while the bottom layer serves as an PCB manufacturer other conductor. Both sides of these layers are etched to create a copper pattern which establishes electrical connections between components.

Characteristics:

The most prominent feature of a Double Sided PCB is its ability to accommodate complex circuits in a compact size. By effectively utilizing both sides of the board, it maximizes space utilization without compromising functionality. This offers greater flexibility during design and assembly processes.

Advantages:

1 Sandwich circuit board structure . Enhanced Density: The dual-layer design allows double-sided boards to achieve higher component density compared to single-sided alternatives.

2. Improved Performance: With separate conductive paths on each side, signal integrity improves leading to better performance and reduced electromagnetic interference.

3. Cost-effective: Despite their advanced functional Top and bottom conductor PCB ity, double-sided boards are still cost-effective due to automated manufacturing techniques.

4. Easy Testing & Maintenance: Accessibility from both sides makes testing and troubleshooting easier, saving time during diagnostics or repairs.

Usage Methods:

Double sided boards find applications across various industries including telecommunications,

consumer electronics appliances li

ke smartphones,

computers automotive systems home automation products industrial machinery etc.

Their versati Dual layer PCB lity allows them to be used in simple low-density designs as well as highly complex devices that require dense routing capabilities complexities arising due ti comonents nesecitated by multilayer pcb fabrication being ruled out

How To Choose:

Selecting the right Double Sided PCB manufacturer is crucial to ensure a high-quality product. Consider the following factors during the selection process:

1. Expertise: Look for manufacturers with proven expertise in producing double-sided boards for your specific industry requirements.

2. Certificat

ions: Ensure that the manufacturer follows international standards and holds necessary certifications like ISO 9001, UL, etc.

3. Technology Capabilities: Examine their manufacturing capabilities, equipment, and materials used to ensure they are up-to-date with the latest technologies.

4. Prototype Services: Opt for a manufacturer who offers p PCB manufacturer rototype services to test designs before full-scale production.

Conclusion:

In conclusion, Double Sided PCBs have become an integral part of mode Double Sided PCB rn electronics due to their compact size, enhanced functionality, and cost-effectiveness. The sandwich circuit board structure facilitates complex designs while maintaining optimal performance levels. When selecting a Double Sided PCB manufacturer, it is vital to consider their expertise and technological capabilities to ensure superior-quality products meeting specific industry requirements.

As technology advances further, we can expect double Double Sided PCB -sided boards to evolve even more in terms of density and performance capabilities—catering to the growing demands of various sectors worldwide