Alloy Steel Plate: Manufacturing, Features, Advantages, Usage and Selection Guide

Introduction:

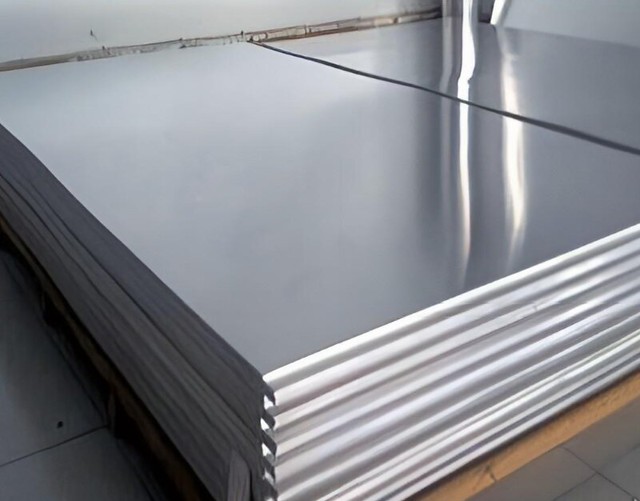

Alloy steel plate is a widely used material in various industries due alloy steel plate to its exceptional strength and durability. It is composed of different elements, such as carbon, manganese, nickel, chromium, and molybdenum. In this article, we will explore the manufacturing process, features, advantages, usage methods of alloy steel plates along with a guide on how to select the right product.

Manufacturing Process:

The manufacturing of alloy steel plates involves several steps to ensure high quality and performance. Firstly, carbon steel manufacturers carefully select the raw materials based on specific requirements. These materials underg carbon steel manufacturer o rigorous testing for their chemical composition and physical properties. Once the appropriate mix is achieved with added alloys like nicke Composite steel plate l or chromium,the molten metal is poured into molds in order to form slabs or billets.

Next,the slabs are heated at high temperatures,either by rolling or forging,to reduce thicknesses.These sheets are then cooled gradually through heat treatment processes,such as annealing or quenching,to enhance its structural properties.Multiple passes may be required during the rolling process,different grades,and sizes can be produced according to specific needs.

Features:

Steel alloy panels have unique properties that make them suitable for various applications.They possess excellent corrosion resistance,prominent m Steel alloy panel echanical strength,and good weldability capabilities.Additionally,having high tensile strength even at elevated temperatures allow them to withstand heavy loads without compromising structural integrity.Alloy steel plates also exhibit superior toughness,making them ideal for challenging environments where impact resistance,toughne alloy steel plate ss under extreme conditions are required.Moreover,various grades combination helps balance hardness versus ductility according to desired specifications.

Advantages:

Using composite steel plates offers several advantages over other types of materials.One significant advantage is their cost-effectiveness compared to pure metals while still providing comparable

performance.Its versatility enables it’s widespread use within construction,mining,oil & gas,automotive,shipbuilding,and many other industries.Their excellent corrosion resistance significantly extends the lifespan of structures, reducing maintenance carbon steel manufacturer and replacement costs. Furthermore,since alloy steel plates are readily available in different sizes and grades,it allows for greater design flexibility to meet specific project requirements.

Usage Methods:

Alloy steel plates find extensive applications in a myriad of industries.For example,in construction projects,they provide structural support for buildings,bridges,and infrastructure requiring high load-bearing capacities.In automotive manufacturing,the composite steel plate is widely used for bodies,floor panels,chassis components,to ensure safety and durability.Some marine vessels also utilize these plates due to thei alloy steel plate r ability to withstand harsh weather conditions.These versatile materials can be fabricated into various shapes like cylinders or pipe fittings making them suitable for pressure vessels & pipelines.

How to Select Alloy Steel Plates:

Selec

ting the right alloy steel plate is crucial to achieving desired results.Firstly,determine the specific application requirements such as strength,capacity,and temperature resistance.Considerations should include choosing appropriate grades based on mechanical properties like tensile strength,yield strength required.Furthermore,evaluate the chemical composition,surface hardness level,and performance under extreme conditions.Verify certifications meeting international standards such as ASTM,AISI,JIS make it an important consideration.Lastly,discuss with experienced suppliers who can provide technical guidance while considerin

g factors like delivery time,cost competitiveness,reputation,& after-sales support.

Conclusion:

In conclusion,the use of alloy steel plates offers numerous benefits across various industries.From its efficient manufacturing process through careful material selection,to its exceptional features including h Compound alloy panel igh strength,toughness,machinability & corrosion resistance;alloy steel plate proves itself indispensable.As one explores usage methods across sectors ranging from construction to automobile sector,this product exhibits versatility.It’s important when selecting products,to consider diverse specifications regarding grade,size,application-specific needs.To procure optimal perfo alloy steel plate rmance sourcing from reliable suppliers providing adequate technical advice assists procurement teams tremendously. With ever-growing demands for quality-built structures or machinery, utilizing alloy steel plates guarantees excellent results.