Alloy Steel Plate: The Ultimate Guide

Introduction:

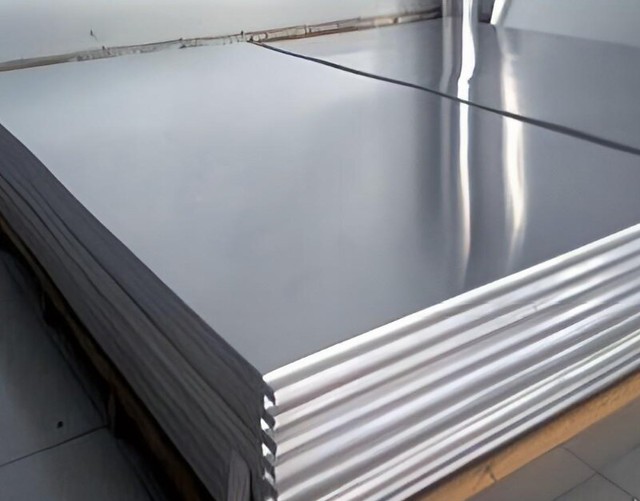

In the world of construction and manufacturing, alloy steel plate plays a vital role. This versatile material offers exceptional strength, d

urability, and corrosion resistance. In this comprehensive guide, we will explore everything you need to know about alloy steel plates.

Section 1: Manufacturing Process

Alloy steel plates are produced using advanced techniques that involve combining multiple metals to create a final product with enhanced properties. The alloy steel plate process begins with selecting high-quality raw materials such as carbon steel and various alloys like nickel, chromium, or manganese. These materials are melted together in a furnace at extremely high temperatures until they become molten liquid known as fusion steel sheet.

The next step involves pouring the molten metal into mo Composite steel plate lds of different shapes and sizes to form metal alloy plates. These plates undergo further heat treatment processes including annealing and quenching to strengthen their structure. Finally, the plates are rolled or forged to achieve the desired thickness.

Section 2: Characteristics and Advantages

Alloy steel plates possess several characteristics that make them highly desirable in numerous industries:

1) Exceptional Strength: Alloy steel has significantly higher tensile strength compared to regular carbon steel. This enables it to withstand heavy loads without deformation.

2) Enhanced Corrosion Resistance: The addition of specific alloys provides excellent resistance against rust and other corrosive elements.

3) Improv alloy steel plate ed Hardness: Alloy steels offer superior hardness levels which make them suitable for applications requiring wear resistance.

4) Excellent Machinability: Due to its well-balanced composition, alloy steel is relatively easy to machine into complex shapes.

These remarkable features give alloy steel plate a competitive edge carbon steel manufacturer over other materials such as stainless or carbon steels.

Section 3: Applications

Due carbon steel manufacturer to its outstanding properties, composite steel plate finds extensive usage across various industries:

1) Construction Industry: Alloy steel plates are widely used for building structures that require immense strength like bridges, skyscrapers, and offshore platforms.

2) Automotive Sector: Alloy steel plates are vital components in manufacturing car frames, chassis, and other structural parts that demand high strength and durability.

3) Oil and Gas Industry: These plates are extensively used for con alloy steel plate structing pipes, storage tanks, and pressure vessels due to their resistance against corrosion.

Section 4: How to Select the Right Alloy Steel Plate

Considering the wide range of available options is crucial when selecting alloy steel plates for a specific application. Here are some factors to consider:

1) Strength Requirement: Determine the maximum load or stress your project will impose on the plate.

2) Corrosion Resistance: Assess the environmental conditions where the plate will be used; choose an alloy with suitable resistance properties accordingly.

3) Temperature Limitati Fusion steel sheet ons: Consider whether your project involves elevated temperatures or extreme cold environments; select an alloy that can withstand such conditions.

Section 5: Conclusion

Alloy steel plate offers exceptional strength, enhanced corrosion r Metal alloy plate esistance, improved hardness levels, and excellent machinability. It is widely used in various industries due to its superior performance characteristics. When choosing an alloy steel plate for your specific needs, carefully evaluate factors like strength requirements, corrosion resistance properties, and temperature limitations.

In conclusion,you now have a comprehensive understa alloy steel plate nding of alloy steel plates – from their manufacturing process to their key advantages and applications. Make informed decisions while selecting these materials based on your project’s needs to ensure reliable performance and long-lasting results.