Double Sided PCB: The Ultimate Guide

Introduction:

In the world of electronics, printed circuit boards (PCBs) play a cruc Double Sided PCB ial role in connecting various components and enabling smooth functioning of electronic devices. Among different types of PCBs, double-sided PCBs have gained PCB supplier immense popularity due to their versatility and reliability. This article will provide an in-depth understanding of double-sided PCBs, including their manufacturing process, characteristics, advantages, usage methods, tips for selecting a supplier or assembly service provider, and a conclusion.

Content:

I. Manufacturing Pr PCB Assembly ocess:

Double-sided printed wiring boards are manufactured using advanced technology that involves multiple steps. Firstly, a thin layer of conductor material is applied on both sides of the base material through etching or deposition techniques. This base material can be made up of various materials like FR-4 epoxy resin or flexible polyimide sheets.

II. Characteristics:

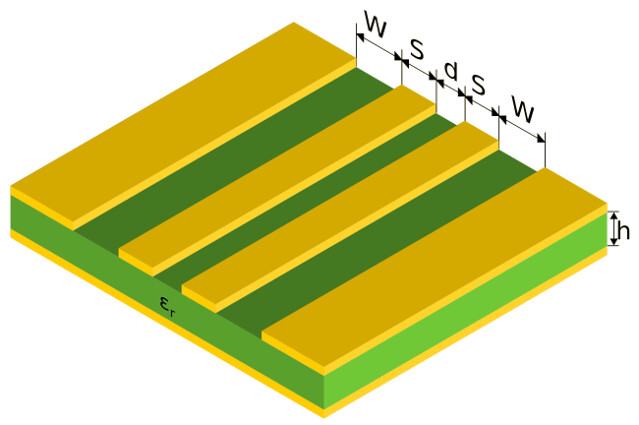

1. Top and Bottom Conductor PCB – Double-sided PCBs have conductive tracks on both sides which a Sandwich circuit board structure llow for greater flexibility in routing sign Double-sided printed wiring board als.

2. Sandwich Circuit Board Structure – With two layers sandwiched together by insulating substrate layers increases the board’s durability.

3.Twin-panel Circuit Board – It has copper trace on top as well as bottom surface.Providing extra space for highly populated designs

4.Two-layer Printed Circuit Board-The most common type known in industry

III. Advantages:

Double sided pcb brings along n

umerous benefits for electronic device manufacturers and designers alike.

1.Effectiveness-Because they offer ample routing area so more compactness then single layered pCB

2.Space-Efficient: Utili

zes smaller footprint due to routing opportunities on both sides

3.Compatibility-Widely used due to compatibility with through-hole integrated circuits (ICs)as well mounting Surface Mount Devices(SMD).

IV.Usage Methods:

The applications of double-sided PCB range across a wide spectrum:

Consumer Electronics such as smartphones,camera,mobiles etc.

Industrial Equipment: including power supplies, control panels, and automation Double Sided PCB systems.

Automotive Applications:engine control modules,sensor circuits,timing controls e Top and bottom conductor PCB tc.

V. How to Select the Right Double-Sided PCB Supplier or Assembly Service Provider:

When selecting a double-sided PCB supplier or assembly service provider, consider the following factors:

1.On-time delivery of products

2.Quality assurance and certifications (ISO 9001)

3.Customization options

4.Outstanding technical support

5.Competitive pricing

VI.Conclusion Double Sided PCB :

Double Sided PCBs have revolutionized the electronics industry with their advanced features and versatility. Whether you are an electronic device designer or manufacturer,it is crucial to understand the manufacturing process, characteristics, advantages,and usage methods of double-sid Double Sided PCB ed PCBs.With proper consideration of these factors,you can make an informed decision while selecting a reliable supplier for your specific requirements.