Fiber Optic Terminators for Autonomous Vehicles

The reliability and security of a fiber network are critical to enabling seamless connectivity for autonomous vehicles. Redundant fiber paths and backup systems ensure continued communication in case of network failures or interruptions.

Proper installation and maintenance practices reduce signal losses. This includes ensuring that the ends of the fiber are cleanly cut and polished to prevent rough edges that can scatter or absorb signal light.

High Speed and Bandwidth

Fiber optic communications technology is more advanced than traditional hard-wired systems, providing higher data transfer speeds and a larger bandwidth. It can carry multiple signals over long distances with minimal loss fiber-optic-terminators-light-trap of quality, and it can support both voice and video transmissions. It also offers immunity to electromagnetic interference and is resistant to tapping (eavesdropping).

Fiber-optic networks allow users to enjoy faster download speeds, as well as symmetrical uploads, which is particularly beneficial for businesses that host large file transfers. In addition, they are highly durable and have resistance to environmental factors that would negatively impact other types of communication equipment.

Proper fiber optic termination is essential for achieving high-speed connections. This includes using the right tools, adhering to industry standards, and performing regular quality checks. This ensures that the connections will perform as intended and minimizes signal loss over long distances.

By leveraging the benefits of fiber-optic communication technologies, railway operators can achieve higher data transfer speeds, greater bandwidth capacity, and enhanced network reliability. However, challenges such as installation and maintenance costs, technical expertise requirements, and cybersecurity concerns must be addressed for optimal performance.

Low Latency

For high-speed, long-distance communications, fibers are the preferred choice over electrical cables. Infrared light travels much more quickly through optical fibers than electric current does through metal wires, and optical signals are far less susceptible to electromagnetic interference, allowing many channels to be transmitted over relatively long distances with minimal loss (net data rate is per-channel data rate minus overhead bytes).

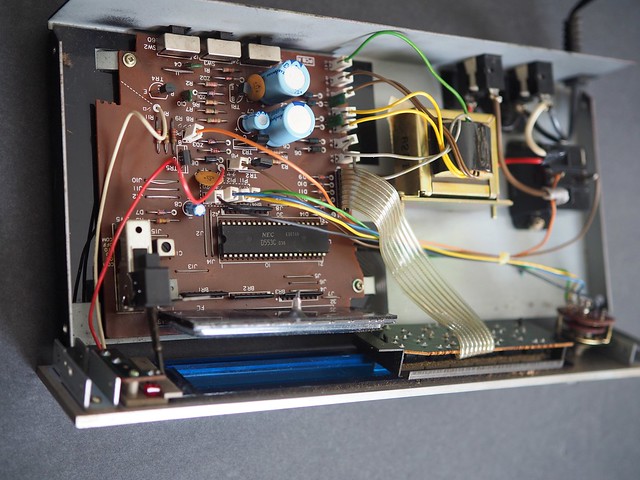

Fiber optic network cable can be terminated in two ways – with connectors that can mate two fibers to create a temporary connection and/or connect to a piece of network gear, or permanently with a splice that joins the ends of the fibers together into a single continuous optical waveguide. Optical fiber connectors include ST, FC, LC, MTRJ and MPO types. A splice is accomplished by melting the ends of the fiber with an electric arc, or, for quick, simple connections, using a mechanical method.

An advantage of the ion trap design described above is that the polarization maintaining fiber used to deliver laser light and to collect fluorescence is directly embedded within the trap structure, eliminating the need for optical windows. This improves state detection fidelity, ensuring the correct transition between bright and dark states of the trapped ion.

The critical angle for a particular optical fiber is defined by the maximum angle at which light can enter and propagate down the fiber without leaking out of the core. The sine of this value, often reported as the numerical aperture, determines the range of wavelengths that can be efficiently coupled into a given fiber, and also influences the amount of dispersion (frequency-dependent delay) in the transmission system.

Immunity to Electromagnetic Interference

Smiths Interconnect offers a wide range of fiber optic connectors to fit the various styles of optical fiber. Our multimode and single-mode connectors support high bandwidth applications. They are designed to mate and seal with precision in order to provide minimal light loss. Moreover, they are installed in a way that protects the connections from dirt and other damage.

The physical principles governing fiber-optic routing are fascinating, and the technology behind it has allowed revolutionary advancements in telecommunications and internet connectivity. These thin strands of pure glass or plastic carry digital information as pulses of light.

Optical fibers contain both a core and an optical cladding that traps the light. The core has a lower refractive index than the cladding. When light strikes the edge of the cladding gytc8s-fiber-optic-cable-arial-and-ftth at an angle greater than a critical value, known as the acceptance cone, it is reflected back into the core and guided down the fiber. This process is called total internal reflection (TIR).

This technology allows the transmission of data over long distances with low attenuation and resistance to electromagnetic interference from nearby power lines and radio signals. Moreover, fiber is immune to tapping and eavesdropping, unlike copper cable. This makes it ideal for mission-critical applications that require redundancy and secure communication. It also eliminates the need for costly repeaters and switches.

Miniaturization

Optical fibers are used to convey data, signals, and information over long distances. They require a minimum of signal loss, which is largely dependent on the geometry of the fibers. This is because the light that travels through an optical fiber cannot cross at more than a small range of angles from the center. This maximum range is called the acceptance cone. The smaller the acceptance cone, the less light will leak out of the fiber.

Unlike copper cables, which have large connectors that create significant cable losses, optical fibers utilize tiny connectors with much lower losses. This allows for greater flexibility and faster installation, which are important in remote sensing applications that require real-time monitoring and data collection.

The end-face of an optical fiber connector must be clean to avoid signal reflection that causes data loss. Typical airborne dirt and oil present on the end of the ferrule will cause this reflection, and it is therefore essential to regularly clean optical fiber connectors using lint-free wipes and specialized cleaning solutions.

A light trap can be incorporated into the optical fiber termination to prevent reflections from occurring at unused ports in the system. This is helpful in preventing unwanted return losses that degrade the performance of the entire system. It also makes it easier to connect and disconnect equipment in the field without worrying about losing valuable data.