How to Create a Glow in the Dark Party With a Photoluminescent Pigment

If you are looking for a way to create a glow in the dark party, you can use a photoluminescent pigment. This is a very special type of material which emits light for up to three years. You can use this type of material to make art crafts, such as jewelry, or to decorate items for your Halloween party. The materials that are used to create this type of material are not hazardous to humans. In fact, the pigment is completely safe.

Glow in the dark paint

A photoluminescent pigment, also known as glow in the dark paint, is a powder that glows after being exposed to light. This type of pigment is used in paint, plastics, fibers and other transparent media. It’s safe to use and has a lifespan of at least 10 years.

The main component in glow in the dark paint is strontium aluminate, a non-radioactive compound. The resulting luminescent nanoparticles are persistent.

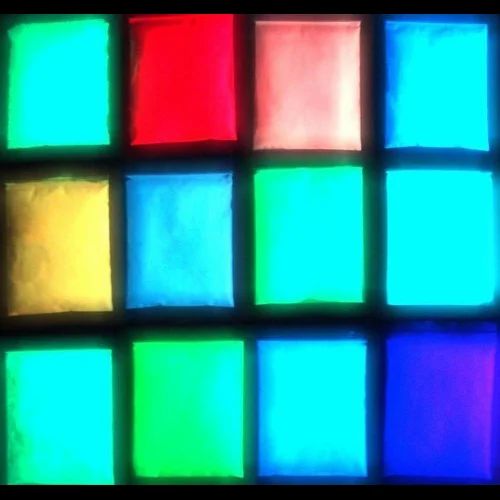

Photoluminescent pigments are used in many areas of communication, including consumer goods, signage, and military facilities. Their glowing time depends on the energy charge and the amount of light absorbed. These pigments are available in many forms, from powders to crystals.

Commercial strength photo luminescent pigments have a bright and vibrant color that glows in the dark. They are ideal for craft projects and decorative purposes. For best results, they should be used with a clear coat. Using a clear coat will protect the pigment from dust and UV rays.

Glow in the dark powder can be mixed with water-based or spirit based mediums. However, the glow pigment should have a high concentration on the surface of the medium. Also, the pigment should be suspended in a transparent medium.

Strontium aluminate is the latest generation of phosphors. Compared to older generations based on sulphured compounds, the latest one has 10 times better glowing power.

Glow in the dark powder

Photoluminescent pigments are used for many different applications. They can be used to make paint, varnish, or any transparent medium. These pigments are non toxic, and can be reused many times. Moreover, they glow for a long time after being absorbed by visible light.

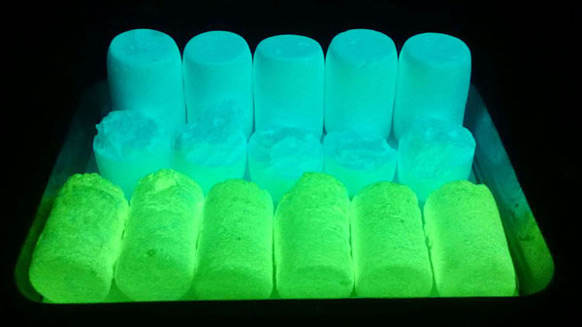

Glow in the dark powders are available in various shades. Some popular ones include green, red, orange, and neutral orange. Depending on the size of the crystals, the intensity of the glow can vary. This type of glow can be a wonderful way to create decorative landscaping features and marking.

The particles are usually around 40 to 65 microns in size, but can be larger. For the best glow, you should mix the powder with a transparent medium. You can use water-based mediums, or spirit based ones.

Glomania has a wide range of glow in the dark powders. Their pigments are specially coated for water usage. With the proper technique, you can even apply this type of pigment with a brush. A 20-gram pouch can make a litre of glow in the dark paint.

There are also special glow powders that are available in fine, coarse, and rare pigments. Specialty colors are great for glasswork, anti-slip flooring, and more. However, these require additional processes.

You can purchase glow in the dark powder at photoluminescent pigment any of the following links. Make sure to check the MSDS sheet to find out whether the powder is hazardous.

Non-toxic, harmless, non-radioactive

For a glow in the dark powder to be considered non-toxic it must have a couple of key features. First of all it must be non-radioactive. Second, it must be able to glow for at least 24 hours. The best thing is that it should be eco-friendly.

As a matter of fact, there are a few different types of glow in the dark powders on the market today. Some of them are very safe and are suitable for use in a wide variety of applications. They are typically made of strontium aluminate and are considered non-toxic.

Another type is called a phosphorescent pigment. It is created when strontium aluminate is combined with rare earth metals such as europium or dysprosium. When these rare earth elements are activated by ultraviolet light, they emit a visible light.

Glow in the dark paints are also available. These products have a glowing effect that lasts for up to five or six hours. This is because the paint contains a small amount of radioactive isotope. You should never breathe in the fumes.

One product to consider is a brand from ECOS Paints. Their product line is available online. Among the ECOS Paints brand offerings are a variety of zero-VOC latex paint. There are also some tinted options.

A third option is to consider a glow in the dark powder that is non-toxic. They should be mixed with a zero-VOC latex paint.

Non-volatile

Non-volatile pigment for photoluminescence is the latest craze amongst coating enthusiasts. Several manufacturers of coatings have responded to the growing demand for low VOC products by developing products with less volatile content. It is important to understand that there is a trade off between the total weight of a coating and the amount of non-volatile material it contains.

There are several methods used to measure the non-volatile matter of a given coating. Some of these include microgram measurements, and volumetric measurements. The ASTM D2832 standard is often used in the paint and coating industry to assess the volumetric content of a coating. This test uses a 30 uL injection to achieve a flow rate of 0.8 mL/min over 50 to 60 minutes.

It is not always the most precise measure, especially when measuring the non-volatile matter of varying concentrations. For example, a single milligram of an anthocyanin (Cy-3,5-O-diglucoside) eluted in a liter of ethanol, but a fraction of that was eluted by a quart of a water-soluble medium. Fortunately, a less polar solution such as MeOH was found to be a good choice.

To determine the most efficient method, the color of the pigment, the amount of solvent used, and the type of solvent used in the test were also taken into account. While there was no overall statistically significant difference, the most prominent pigments were those detected in the less polar solvents.

Effects of excitons on luminescence

Exciton luminescence in two-dimensional atomic-layered transition metal dichalcogenides is interesting and intriguing. In these materials, there is large exciton binding energy, valley exciton selection rules, and interesting optical properties. These properties are attributed to the formation of excitonic quasiparticles in the monolayers. Here, we discuss the effect of excitons on luminescence of LuAG crystals. This effect is dependent on the temperature of measurement, the sample preparation technique, and the intrinsic defects of the crystal.

The intensity of the A exciton was strongly affected by the thickness of the layers. We obtained evidence of this photoluminescent pigment phenomenon by mapping the photoluminescence intensity of the individual crystals. Moreover, we analyzed the effects of interlayer interactions on the luminescence of the A exciton.

The B exciton was nearly constant. However, there was a drastic change in the intensity of the A exciton. The change was observed in both the 2L and 1L regions. This was explained by a direct to indirect bandgap crossover. Our results support the hypothesis that the intensity of the B exciton is almost independent of the layer thickness.

Photoluminescence spectroscopy was performed in the UV spectral range. The peak amplitude at 3.59 eV was enhanced in the films with x = 3.75 and 3.80. It was also confirmed by electric-field-tuned PL spectroscopy. Enhanced luminescence is also attributed to resonance between the organic and inorganic layers.

Coating substrates with luminescent pigments

Luminescent pigments are used for coating substrates in a variety of different applications. They can be applied to glass, ceramic tiles, plastics, and more. These pigments are made of organic and inorganic compounds that emit light when excited by an energy source.

Lumilux N and SN phosphorescent pigments are available in a variety of particle sizes. These particles are suitable for a wide range of applications and can be used with both synthetic and natural resins.

Coating with luminescent pigments is an important way to add brightness and visibility to a surface. It is particularly useful for tall structures and surfaces that are hard to view. The process can be done in a variety of ways, including spraying and mixing.

A digital image of the coated surface is taken. This is then analyzed to determine the quality of the coating. In addition, it is noted how much damage has occurred on the surface.

Coating with luminescent pigments also provides unique visual effects. For instance, it can create the illusion of flickering lights or metallic reflection. Moreover, it can allow for infinite design possibilities.

Whether the coated material is textile, glass, or metal, the color changes when exposed to strong UV light sources. However, this effect is less intense on textiles, especially on multifilament yarns.

PMMA Glow In The Dark is a 2-component fast-curing sealing resin that delivers luminescent pigments that are 100% water resistant. These pigments can be applied at temperatures as low as -5 degC.