Lifting Slings: A Comprehensive Gu lifting slings ide to Manufacturing, Features, and Usage

Introduction:

The relevance of load securing slings in various industries cannot be overstated. Lifting slings are essential for safe and efficient material handling operations. In this article, we will explore the manufacturing process, characteristics, advantages, usage methods, how to select the right lifting sling for your needs, and provide a conclusion.

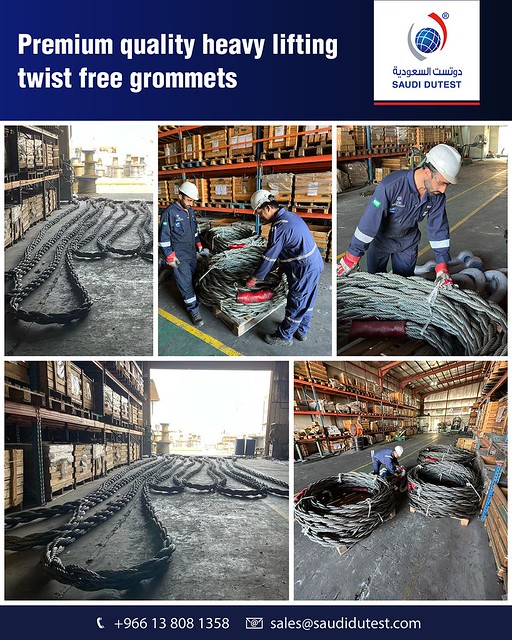

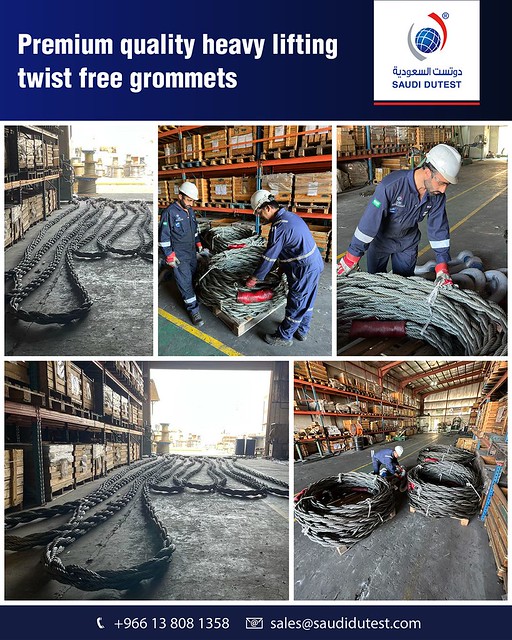

Manufacturing Process:

As an established lifting slings manufacturer and wholesaler, our company foll

ows a meticulous manufacturing process. We utilize high-quality materials such as polyester or nylon to create durable and reliable lifting slings that can withstand heavy loads. These materials are carefully woven together using advanced machinery while adhering to industry standards fo Rigging slings r safety.

Characteristics of Lifting Slings:

Our lifting slings exhibit several key features that make them ideal for various applications:

1. Strength: Lifting slings have except lifting slings manufacturer ional tensile strength capabilities.

2. Flexibility: They are flexible enough to conform to the shape of the load being lifted.

3. Abrasion Resistance: Our slings have excellent resistance against abrasion caused by sharp edges or rough surfaces.

4.Pull-resistant fibers ensure enhanced security during lifting operations.

Advantages of Using Lifting Slings:

1.Safety is paramount when it comes to material handling tasks; hence u lifting slings wholesaler sing quality lifting slings minimizes accidents risks

2.Cost-efficiency: Compared to alternative methods like chains or wires rope rigging solutions

3.Versatility: The adaptability of these products caters well across diverse industries including construction works , marine activities

Usage Methods:

1.Before employing any sling,it’s vital you carry out thorough inspection checking frays,cu Load securing slings ts,distortion,damaged stitching,tangled webbing

2.Choose suitable attachments,hitches ready on cranes,hooks,lifts etc.what ever suits ur requirement

3.Use Sling Angle Limits charts,to determine working angle range

4.Most common hitch methods include Vertical lifting slings , Chocker, and Basket hitches depending on lifting scenarios

How to Select the Right Lifting Sling:

1.Weight Capacity: Ensure that the selected sling has a sufficient weight capacity for your intended load.

2.Safety Factors: Consider safety factors such as workin Cargo straps g conditions, potential hazards, and exposure to chemicals or extreme temperatures.

3.Length and Width: Choose the appropriate length and width of the sling based on load dimensions.

4.End Fittings: Assess the need for specific end fittings like hooks or shackles based on your lifting equipment.

Conclusion:

In conclusion, finding a reliable manufacturer like us is crucial when it comes to selecting high-quality li lifting slings fting slings. Our established reputation precedes us in terms of expertise and experience in designing dependable slings. Consider factors such as manufacturing process compliance with industry standards, characteristics including flexibility and strength advantages above alternative rigging options. Finally using the cor established lifting slings manufacturer rect usage methods ensures smooth operations . Remember to thoroughly inspect each sling before use- prioritize safety above all else!