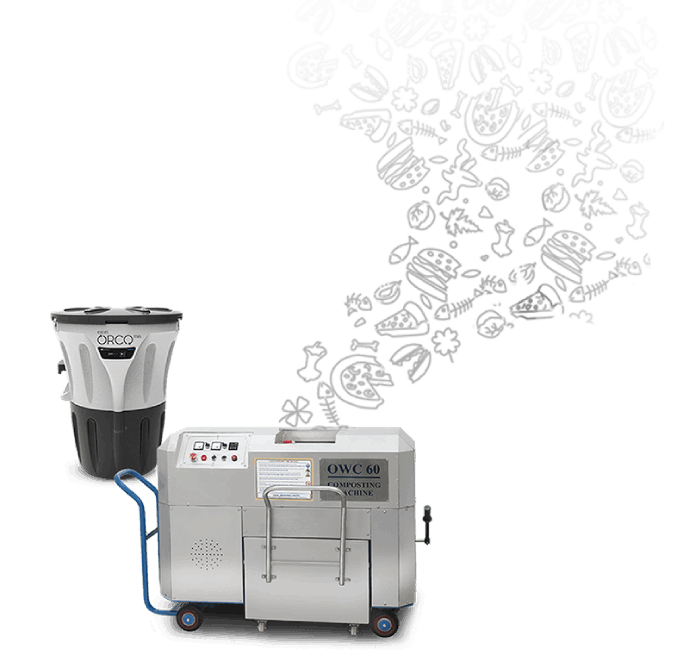

Organic Compost Making Machine

The organic compost making machine is a device which makes the process of producing organic waste for the garden simple. It has several features, which include Automatic deodorization, vertical closed tank structure, and segregation of the organic waste. This device is very popular in residential and commercial areas.

Automatic vs semi-automatic

For people who want to compost, either as a hobby or commercially, an automatic or semi-automatic machine is a must. The machines have a variety of features and are easy to use.

Composting is a process that converts organic waste into compost. This helps to improve soil quality and fertilizers for plants. During the process, harmful bacteria and other pathogens are eliminated. It also releases energy.

An automatic composting machine is a great option for large-scale production of organic fertilizers. It uses aerobic fermentation technology to turn organic materials into useful compost. However, it does take more space than a compost turner.

On the other hand, a semi-automatic composting machine is less expensive and requires only one worker to operate it. In addition, it has less power consumption and no rodent proof infrastructure.

A PLC control system helps to keep track of materials turning. In addition, an automatic discharging system can be used to send composted organic waste out of the machine.

Another feature of the HMI display is the overload function. Basically, it shows how much of the organic waste is in the machine.

A PLC control system also shows you how to achieve better results. Also, the HMI display is attractive and odour-free.

During the process, an air supply system helps to provide oxygen for the microorganisms. Moreover, a temperature sensor can detect whether or not the composting process is complete.

While the automatic or semi-automatic compost making machine is impressive, you still have to put in a little effort and time. The cycle of the machine can take up to 45 minutes for each batch. To achieve better results, you need to mix the materials properly and turn them on a regular basis.

Vertical closed tank structure

In a vertical closed tank structure for organic compost making machine, the first thing to consider is the material. Organic waste must have a carbon to nitrogen ratio of at least 20-30:1. It also must have a PH value of between 7-8.5.

For efficient fermentation, it is important to add water to the manure. There should be a moisture content of at least 50%-70%. The temperature of organic compost making machine the container should be 65-83degC during the fermentation process.

It is recommended to use a five-pallet unit to increase the stability of the bin. Each pallet can be made from wood or recycled plastic.

A turning unit can be used to help mix the materials. You can build a compost bin from materials or purchase one from a mail-order catalog. Depending on your needs, you may choose a three-bin unit or a concrete block holding unit.

Concrete blocks can be placed along the back wall of the unit or stacked up in rows. They are very durable and sturdy. These units are typically more expensive to construct than wire-mesh holding units.

To make a wire-mesh holding unit, you will need chicken wire and hardware cloth. The hardware cloth will need to be trimmed so that the ends are flush with the cross wire. Ties should be used to attach the chicken wire to the hardware cloth. Fold the wire back 3 to 4 inches to provide a clean edge.

You can also purchase pre-fabricated compost bins from a building supply store. This will make it easier for you to turn your organic materials.

Vessel composting equipment can be used to treat agricultural waste such as cattle and pig manure, chicken manure, Chinese medicine waste and sleep manure. Using this equipment can help you recycle organic waste, conserve resources and save money.

Automatic temperature sensor

One of the most important tasks in composting is monitoring the moisture and temperature of the pile. These factors will help you to create a stable workflow. The optimum moisture level for a compost pile should be between 40 to 60 percent.

In addition to measuring the moisture, a thermopile sensor will also show you the temperature of the pile. Ideally, the temperature of a compost pile should be around 50°F. This is because it will allow for aerobic fermentation.

If you’re using a handheld thermometer, you’ll want to go with one that’s built to handle the corrosive conditions of composting. You should also look for one that has a weatherproof head.

To make the most of your investment in a temperature and moisture sensor, choose a system that has a long battery life. You’ll also want to be sure that it’s able to transmit the data.

While there are many options, it’s important to find the best sensor for your needs. A good sensor will allow you to monitor your composting process and increase your overall efficiency.

Keeping track of a number of variables can be difficult. However, the temperature of a windrow must be measured constantly to achieve optimal throughput.

Other factors to watch for include the presence of micro-organisms. This will help to reduce odors and pollution. It’s also good to keep an eye on gas ratios and pH levels.

Another cool tidbit to keep an eye out for is the Solvita. Developed by Woods End Laboratories, this is a kit organic compost making machine that measures the following: a) the number of times the temperature in the pile increases; b) how fast the rate of decomposition increases; c) how much carbon dioxide is released; and d) how much oxygen is consumed.

Automatic deodorization

If you have an organic compost making machine then you will have no trouble making your own organic fertilizer. Besides, the automatic deodorization of organic waste will save you the hassle of dealing with the unpleasant odor.

The main benefit of using an automatic compost making machine is that it is very easy to use. Also, the machine is very efficient. It can produce an organic fertilizer in a short span of time. In addition, it can be operated by one person. Moreover, the hydraulic power system has overload protection. This will help to prolong the lifespan of the whole equipment.

A good automatic compost making machine should also have a temperature control mechanism. This will ensure that the finished product is at the right temperatures.

To ensure that the composting process is a success, you will also need a stirring device. This can speed up the fermentation process. You will also need a PLC control system. Lastly, you will need to adjust the water content of the composting materials. With this in mind, you will need to make sure that you are only using the best materials.

You also need to consider the aeration process. By introducing aeration into the composting process, you can artificially provide oxygen to the materials in the pile. However, if you overwater the material, you will have an anaerobic environment. Anaerobic conditions are responsible for foul odors.

When you are considering the best equipment to use, you might want to consider the SEEC fully automatic composting machine. The machine can be used to produce an organic fertilizer in just 10 hours. Additionally, it can handle multiple volumes. Hence, it is a perfect choice for farms and commercial applications.

Segregation of organic waste

Segregation of organic waste is a very important waste management activity. It helps in better waste disposal and recycles organic materials. Composting is an efficient way to divert solid waste from landfills. However, the existing collection system cannot accommodate the increasing volume of organic waste. Developing countries face a serious challenge in dealing with organic waste.

A study conducted in Shiraz, Iran, was carried out to examine the potential of producing compost from municipal organic waste. The research involved a number of parameters that affect the degradation of organic matter. For example, temperature, moisture, density and chemical composition.

After the process, the final product was tested for phytotoxicity and heavy metals. All samples were free of pathogens and showed lower concentrations of heavy metals than Iranian and German standards. Moreover, the EC and C/N ratio were also acceptable.

Results of the study revealed that the compost produced by this method was highly fertile. Furthermore, the final product was smaller than the raw material. This was due to a large amount of moisture in the raw materials.

During the process, the mass loss ranged from 18.9% to 57.9% of the initial volume. The turning schedule was based on the moisture content in the compost. Hence, the piles were turned once a week.

The resultant compost showed low levels of heavy metals. However, it was not yet compliant with the Iran national compost standard. Besides, the phosphorus concentration in the final product was not sufficient to meet the Iranian standards.

Considering the findings of this study, it can be concluded that the production of high-quality compost can be achieved through windrow composting in open site areas. However, it is necessary to develop a plan for upgrading the source-separation collection system.