Ceramic Stains and Glazes

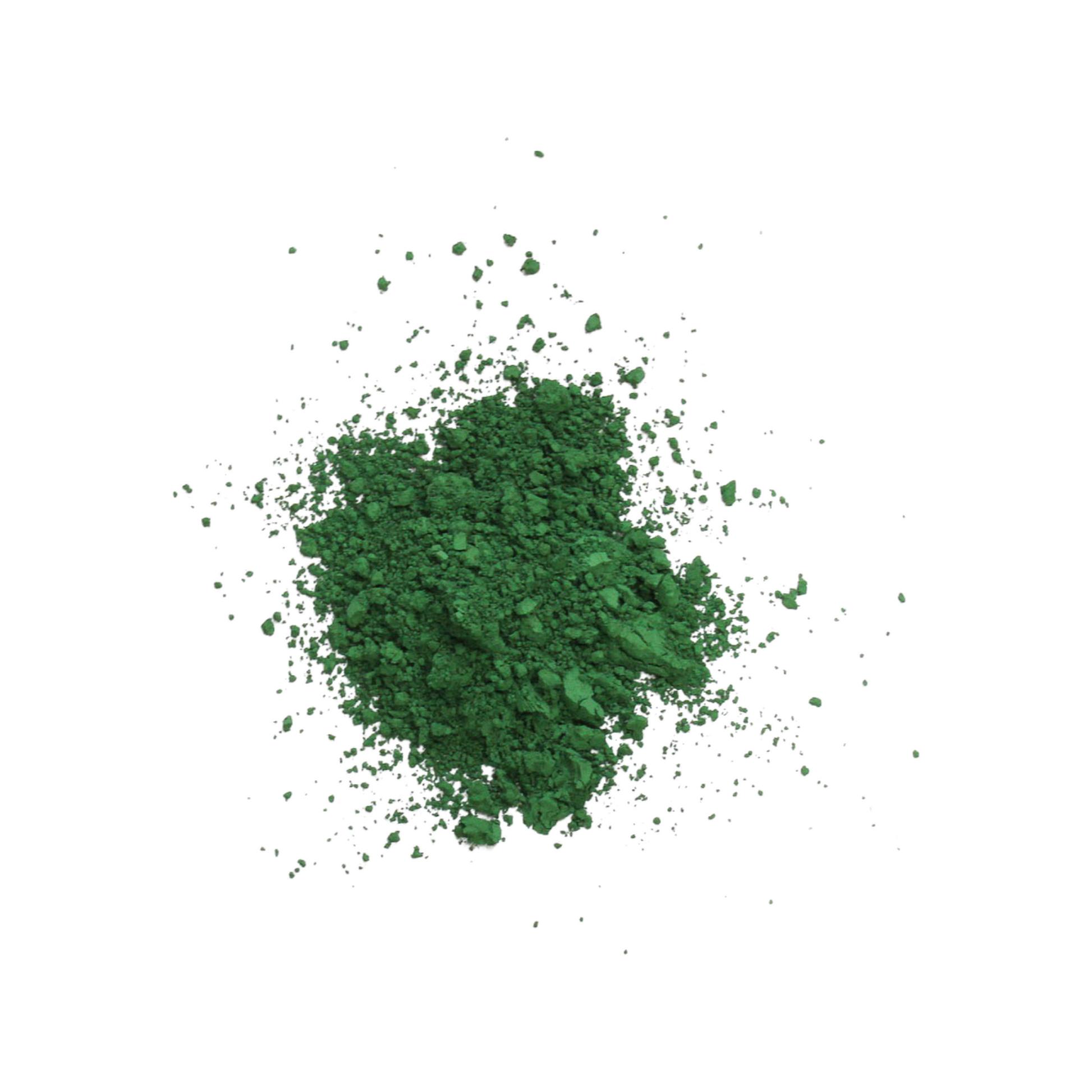

Stains are man-made colorant powders that can be used in glazes, slips or bodies. They are a good choice for decorating ceramic work because they are dependable and stable.

However, stains do have their own idiosyncrasies and must be tested to ensure they are compatible with your host glaze. Check guidelines from the stain manufacturer.

Color intensity

Ceramic stains are produced using pigments that have the optimum properties for firing at high temperatures. These can be either inorganic or organic. They have to be chemically inert in the glaze melt and temperature resistant. They must also have the optimum particle size. They must be able to disperse in the molten glass/glaze matrix and ensure maximum interaction with the light.

Stains can be used on clay bodies (over or under glazes), and can be used to display texture, surface work or brushwork designs. They can also be used for opacification or color development.

The color intensity of stain pigment depends on many factors, but most importantly the granulometric sizes of the particles. When the pigment particles are of the optimal granulometric size, they have the strongest possible color value.

If the particles have larger granulometric sizes, they have less color value. This is because they tend to dissolve more easily into the glaze than they do at their optimal granulometric size of 3 to 4 mu.

These granulometric sizes are determined by the pigment crystal structures, their solubility in molten silica and the mobility of the elements within the crystals. Some crystal structures are very stable, while others have a low melting point and solubility.

Some of these crystals have a low refraction index, meaning that they can diffuse more freely stain pigment for glaze in the glaze. This can lead to a less uniform appearance.

However, this can be corrected with the addition of other oxides. Adding 2-3% Zircopax can brighten the color, or 3% Titanium dioxide can make it more variegated and slightly opacifying.

Another factor that affects the color intensity of stain pigment is the percentage of pigment used in the glaze. This percentage depends on a variety of factors, including chemistry and the type of stain being used.

For example, if you want a red stain, you need more of the pigment than if you want a gray stain. A red stain might require 15% of the total pigment. A gray stain might only need 1% of the total pigment.

In terms of percentage, it is best to consult with the manufacturer to find out what is recommended for a particular stain. They will be able to tell you the amount of each element necessary for a particular color. They will also be able to give you guidelines for chemistry compatibility.

Compatibility with other glazes

Glazes and stain pigments interact chemically when fired, and this can produce a variety of colors on a piece. However, this interaction can also create problems, such as blistering or crawling. To avoid these problems, it is best to mix a range of glazes that have been tested for compatibility before applying them.

The color in ceramics is determined by a combination of oxide systems and how well the glaze melts during firing. In addition, the amount of metal used in a glaze can affect its color.

Some minerals, such as iron and copper, give red, orange, and yellow hues. Other minerals, such as chromium, rutile, cadmium-selenium, and vanadium, can also affect the color of a glaze.

Cobalt and copper are commonly used to produce intense blues, while lead produces yellowish orange hues when melted at lower temperatures. Likewise, uranium and praseodymium are often used to produce reds, oranges, and yellows.

These stains are compatible with most glazes within their own range. They may also be mixed with other glazes to develop new colors. The stains can be added to the base glaze as necessary for the desired effect, but this may reduce the stability of the stain, especially at higher temperatures or in reduction atmospheres.

Most glazes are available in either liquid or dry form, and can be found at your local hardware store. Liquid glazes are packaged in non-breakable plastic jars, while dry powder glazes are sold in a 5 gallon bucket.

If you have a problem with a particular glaze, you can contact your local pottery supply shop to ask if they carry it. They will usually have a good idea of what to suggest, or can help you find the right product for your needs.

Besides the fact that they may be able to tell you what sort of compatibility issues might exist, they may also be able to recommend certain types of clay body that will work with their glazes. This information is important when purchasing a glaze because it will allow you to choose the right type of ceramic body for your project.

Percentage

Prepared ceramic pigments, commonly referred to as stains, expand the potter’s palette with infinite possibilities. Stains are melted in kilns, quenched and ground to specific mesh size (some are acid washed).

They can be used in both glazes and slips for engobes and coloration. The concentrations needed to produce the desired colors are usually 5% or less for a transparent glaze and 10% or stain pigment for glaze more for a white glaze, depending on the base and the firing temperature.

Some stains are refractory and cannot be fired on raw clay surfaces, so they need to be mixed into a melt medium that envelops the particles and bonds with the body below or glaze above. This medium should not melt too much to prevent the colors from bleeding into the over or under-lying glaze.

It is also important to use a low application thickness when using stain because it can peel off during the drying, glazing and firing stages. The thickness of the application should be no more than about one to two millimeters thick.

A simple way to determine the percentage of a stain pigment is to dip a test tile in it and see how much it soaks up. Then you can add that amount to the base of your glaze and dip another test tile until you are satisfied with the final results.

You can even try experimenting with different stain colors and base glazes to see how they interact. For example, if you’re using a chrome-tin pink system in a cone 6 satin matte base and adding an 8% 6213 Mason Hemlock green stain, the glaze will seem to not melt as well and the surface will be more matte.

The solution to this is to adjust the base, either by employing a 90:10 or an 80:20 mix of matte and glossy clear to give the glaze more fluidity.

Lastly, it is important to use a high-quality stain that is produced by a company that offers good service. You should not skimp on quality when choosing a stain because it can make all the difference in the results you get!

Food safety

Stain pigments are made from a combination of metal and ceramic oxides that are ground into a powder. They can be added to glazes or slips as a colorant. The pigments can be used to create colors that are either transparent or opaque.

Pigments are often added in concentrations of 1-10% of the total volume of the base glaze. This will provide the most intense fired color.

Many stains contain ingredients that can be harmed by contact with food, including some acidic foods such as orange juice. This is why it is important to read the label and follow the manufacturer’s instructions when using a stain.

Some stains are also soluble in water, which can make them difficult to clean up. This is a reason that you should never use stain-containing ware in the dishwasher or on the stovetop without first washing it by hand.

If you do use stains in your glaze, it is best to use a lead-free ceramic stain that contains no iron or zinc. Zinc can cause a variety of problems, including affecting color intensity and causing glazes to flow when firing.

It’s also best to avoid working with fritted stains or oxides because these materials are likely to be soluble and toxic. In addition, fritted stains and oxides may interact with other elements in the glaze, creating unwanted colors.

Another factor to consider is whether a stain pigment is suitable for your application. The type of stain pigment you choose, the amount of stain pigment in your glaze, and your glaze’s firing schedule will all affect the quality of your final work.

While most glazes are safe to use with food, some may not be. Some of the most hazardous include low-fired lead glazes, which can leach dangerous amounts of barium and lithium into food.

High-fired glazes can be even more hazardous, since they are often contaminated with toxic metals. The most common toxic metals in these glazes are cadmium and lead, which can leach into food during the firing process.

However, it is also important to note that some stains are safe to use in food if they are formulated with ingredients that are not toxic. These include boron, zinc, and calcium.