Rack Upright Roll Forming Machine

Storage racks are material handling systems that allow for the storage of materials on pallets. They are commonly comprised of beams, wire decks, and uprights.

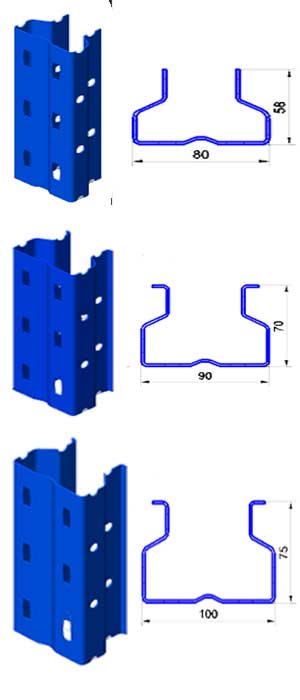

Upright Racks (also called Uprights or Upright Columns) vary in size and design depending on the load capacity and styles. Holes(Tear Drop Design) and slots are punched during producing so that the load beams can be mounted into the Upright Racks.

Precision

Upright Racks are the main part of the shelving system in supermarket and warehouse and even homes. They are available in a variety of widths and designs. They are also commonly used for storing and protecting other products such as food, clothing, furniture, and many more.

LOTOSFORMING offers different cold-forming machines that are suitable for forming various types of uprights. They include the Shelf Back Layer Roll Forming Machine, the Rack Bracing Roll Forming Equipment, the Rack Roll Forming Machine, the Shelf Stud Roll Forming Machine Maker, the Rack Upright Column Roll Forming Machine and other different cold-forming machines.

The Shelf System Upright Rack Roll Forming Machine is a piece of equipment that is used to produce shelves in supermarkets and warehouses. It consists of an uncoiler, a leveling machine, a punching device and a roll forming machine. It is capable of forming different kinds of uprights and cutting them to specific lengths.

Our Shelf System Upright Rack Roll Forming Machine can be customized based on customers’ needs and specifications. It consists of an auto/manual de-coiler, a guide frame, lever/feeding section, continuous hole punching section, a forming section, positioning and cutting section, a collection table and electrical control system.

It is suitable for a wide range of steel sheets and can be customized to meet the customer’s specifications. It is equipped with a strip feeding system, which is an important component of the overall system and ensures that the right raw material is supplied to the roll forming machine at all times.

This equipment is highly automated and can change a coil in under 3 minutes. It is also safe and efficient to operate. It can save labor costs, which is an added benefit.

This rack upright roll forming machine is made of high-quality stainless steel and is able to withstand extreme temperatures. It is equipped with a cooling system, which keeps it from getting hot during long periods of operation. It is also easy to maintain and clean. It is a great choice for manufacturers and can be used to produce a wide range of products.

Accuracy

Rack Upright is a big part of any warehouse pallet racking system. Aside from supporting the load beams, it also plays a significant role in keeping the shelves and racks tucked away neatly in the aisles. The Upright o the gens can be configured in a variety of ways, ranging from stacked and angled to freestanding. The best way to go about this is by enlisting the assistance of an experienced installer and a well-trained team. The most successful installs are usually a result of careful planning, well executed execution and a little bit of hard work on the part of both parties.

Our company has been manufacturing and delivering a variety of high quality, cost effective solutions to our valued customers worldwide for over 20 years. Our specialized line of products, including the rack upright roll forming machine, have earned our place as one of the leading manufacturers in this field. We are proud to have a reputation for providing the highest quality and most reliable machines on the market. If you have a particular product in mind, be sure to contact us to discuss your requirements.

Durability

Upright racks are the main part of the shelves in supermarkets and warehouses, and they are also rack upright roll forming machine used in homes. They are available in 80 width, 90 width and 100 width. They are mainly composed of beams, wire decks and uprights.

The upright roll forming machine is one piece of equipment that is used for making Pallet Rack Systems. The machine can finish holes punching, cold roll forming and cutting the upright to a certain length.

This rack upright roll forming machine can produce different sizes and thicknesses of rack uprights for Warehouse Pallet Rack System. These uprights vary in size and design depending on the load capacity and styles. The uprights are usually thick up to 3mm, and holes (such as tear drop design or utterfly design) and slots are punched on line or off line during producing so that the load beams can be mounted into them.

It has a decoiler, servo feeder, hole press, main roll forming machine and hydraulic shear units. It can process cold rolling steel, hot rolled coils, galvanized coils and general carbon steel.

In addition, it can produce a variety of rack columns and crossbeams in different specifications. It possesses rational and beautiful structure, strong carrying ability and stable and reliable performance. It is controlled by PLC and is easy to operate.

After forming, the finished rack uprights will have good profile section and accurate cutting length. The whole production can be carried out without any downtime and with high productivity.

Moreover, the machine can be easily maintained and adjusted. It can be operated by workers who do not have a lot of training.

The machine is driven by a gearbox and electronic motor. It can form thick hard material like stainless-steel, copper and so on. It has roller mounts on an 80 rack upright roll forming machine mm diameter shaft for long time usage by various forming speed.

This storage rack roll forming machine can be used to make square upright racks for Warehouse Pallet Rack and Logistic Storage Rack System. It is highly suitable for the application of high-end warehouses and logistics stores, as well as factory warehouses.

Flexibility

A Rack Upright Roll Forming Machine (also called Omega-Racking Upright Roll Forming Machine) is a high quality tool that can be used to make racks for Warehouse Pallet Rack System. Its sizes and thicknesses are adjustable and customized. Its forming technology uses the combined type air operated friction clutch and multi-stage punching press to produce the racks.

This machine is designed by LOTOSFORMING, which is one of the top-ranking rack making machine manufacturers in China and specializes in designing and manufacturing these machines. It consists of a manual decoiler and leveling system, mechanical press machine with punch die and roll forming machine part, output table, hydraulic pump station, and electrical control cabinet.

The main feature of this equipment is the ability to form various types of storage racking in a single line. It can be used to produce racks for both light and heavy-duty shelving systems.

Typical applications include industrial racking, e-commerce racks and supermarket shelves. The resulting products are durable, attractive, and easy to maintain.

Its unique design features include a clever servo feeder, which feeds material into a punching press that can input various groups of different feeding lengths. Its multi-stage forming roll enables it to form the racks in a variety of shapes, sizes, and thicknesses.

In addition, its patented technology can also be used to cut racks into different lengths. This makes it an excellent choice for manufacturers looking to save space and money.

With its innovative technology and quality construction, this rack making machine is the perfect solution for a wide range of applications. It can be incorporated into an existing production line or set up as a stand-alone unit.

This rack forming machine can be operated by workers without special training. It has an ergonomic design that is comfortable to use and can accommodate multiple workers. It is easy to maintain and lubricate, and it can operate with minimal noise. It is available in various models and can be shipped worldwide. The best part is that it can be modified for the specific needs of customers.