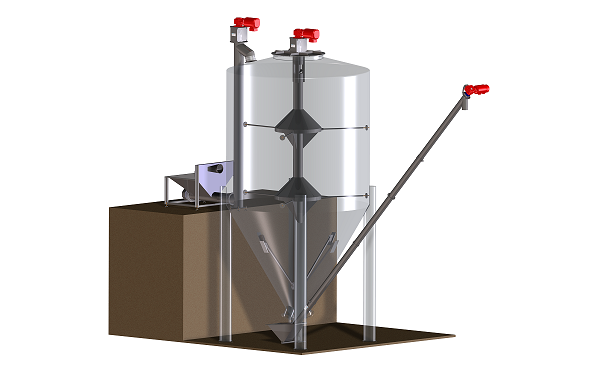

Silo Mixing Buildings

The silo mixing building is a cost-effective, versatile, and durable solution for storing cement and other materials. When used properly, a silo can help reduce waste and increase jobsite efficiency.

Compared to steel options that experience immense levels of corrosion, concrete storage silos are more cost-effective and require far less maintenance. In addition, concrete resists internal abrasion much better than metal, which leads to significant savings over time.

Cost-Effectiveness

Silo Mixing Buildings are a cost-effective way to produce mortar, grout and stucco products. This method of utilizing a silo and conventional mixer helps increase the efficiency of mixing masonry products by eliminating the need for laborers to purchase smaller bags of cement and sand separately. This increases the quality of the masonry mix by eliminating any variances in ingredients, which can result in poor product consistency and ultimately cost you money.

Concrete is an ideal material for a silo because it’s resistant to internal abrasion and can withstand high levels of pressure. It’s also a durable material, making it ideal for long-term use.

However, it’s important to note that not all silos made from concrete are created equal. Some of them are prone to problems that can compromise the safety and performance of the silo. This can be caused by numerous factors, including original defects in the construction and design of the silo.

One of the main concerns is that some silos were originally built before modern design codes and standards were in place. If a silo has deficiencies such as missing or misplaced rebar, poor concrete consolidation, original horizontal lift cracks, inadequate concrete mix, insufficient concrete cover on rebar laps or other original flaws, the lifespan of the silo can be severely limited.

Another issue with silo construction is that as silos age, they’re subject to the wear and tear of weather conditions. If a silo is located in an area where the climate is harsh, a silo wall can deteriorate from cracking or freeze-thaw damage. This can also be exacerbated by the rate of discharge or turnover that is applied to the silo.

A large portion of this wear and tear occurs when silos are exposed to excessive loading or settlement of the subsoil beneath the foundation. When Silo Mixing Building a concrete silo is subject to this type of loading, it can cause the subsoil to lose its characteristics and become brittle or compressible, which may affect the ability of the foundation and subsoil to support the full design load.

This problem can be remedied by reclaiming the subsoil with a suitable fill material that is designed to provide adequate stability and durability. It’s important to consult with your engineer on the correct fill material that will work best for your specific application.

Versatility

A Silo Mixing Building is designed for use in any construction project where a large amount of material is stored and need to be transported to the job site. It’s ideal for storing concrete and other granule-based products, such as asphalt, and it can be used in conjunction with various equipment.

The versatility of silo buildings is one of their main selling points, as they are able to meet the unique needs of each client. This includes a high fluidity of product, ease of access and a high standard of hygiene.

Many of the larger cement silos in Standley Batch’s inventory contain multiple inlet and discharge points, which allows them to handle a wide range of bulk materials. They are also designed to mix different products together, which makes them perfect for a variety of industries.

Depending on your specific needs, Standley Batch can also provide a range of cement silo options to suit your requirements. These include single and multi-discharge, single and split compartment silos.

In addition to silo storage, Standley Batch can also supply conveyors to convey material from the silo to a mixing system. These conveyors can handle a variety of bulk materials, including cement, fly ash and silica.

They have a powerful geared motor and adjustable ball joints for installation below the cement silo, along with sturdy suspension brackets. They can be used in combination with a custom dust control system to keep your silo clean and dust-free.

This enables your employees to work without exposure to harmful contaminants and dust. This helps prevent respiratory illnesses and decreases labor costs for your team.

With a patented mixing action, the Power Blend(r) silo mixer optimizes the processing of dry mortar products with a granularity of up to 6 mm. It can be found on numerous building sites throughout the world, processing bricklaying and insulating mortar, plasters, screeds or fine concrete.

Another popular option is a gravity style silo. This type of silo allows the pre-blended dry ingredients to be pumped directly into the mixer positioned underneath. This eliminates the need for a mixer hopper or bucket to pull the dry materials out of the silo, which can increase safety.

Durability

The durability of a Silo Mixing Building depends on several factors, including the construction quality of the silo, the m aterial used to make it and how it is used. Often, these features can be overlooked by the construction company when designing and building the silo. This can lead to a number of problems including improper concrete coverage, original horizontal lift cracks, poor concrete consolidation and inadequate rebar reinforcement.

Many modern designs and construction techniques provide durability for concrete silos. However, many older silos were designed and built before Silo Mixing Building design codes and standards were in place. This is why it is important to have a professional structural engineer review older silos to identify any limitations that might affect the integrity of the silo.

Another factor that can contribute to a silo’s durability is the quality of the subsoil beneath it. If the subsoil material is not uniform, compressible or does not perform as expected, the silo’s foundation, reclaim tunnel and/or roof will suffer from excessive settlements, resulting in structural damage that may compromise the safety of personnel and/or the operational efficiency of the facility.

Some of the more durable types of silos are wood silos. These are characterized by their use of good grade woods and have been found to preserve the silage in a satisfactory m anner for 10 to 25 years.

Wooden silos have the advantage that their m ost of the w eather is protected from dam age by wind storms and if the proper care is taken to secure a sm ooth finish to the w eather, they will also protect the silage from m oisture and moisture in the air, as well as preventing the silage from getting too cold and becoming hardened or frozen.

Moreover, wooden silos are generally lighter than concrete silos and are easier to erect. They also tend to be more convenient to store, especially if they are constructed with wooden hoops.

Another type of silo that has the potential to be very durable is the slipform type. These silos can be constructed to a diameter greater than 65′ and are most suitable for multiple silos that need to be created at one time. They are also typically the most cost-effective way to build silos of any size.

Environmentally-Friendly

Silo Mixing Buildings are an environmentally friendly option when compared to traditional dry silos. They are also safer and less dangerous to use. This is because they eliminate the need for a power source to mix the materials. Besides, they are also more durable and can withstand the pressures of high-pressure pumps without causing damage to the material.

The silos can be used for a variety of purposes, including storage of grain or other bulk products. They are usually cylindrical structures 30-250 feet tall made of either wood staves, concrete staves, or steel plates.

One of the most popular uses of these structures is to store grains, coal, and cement. This method is called ensilaging and is used by farmers to save money by storing their crops over the winter months when they are not in production.

Another use of these silos is for storing hay, straw, and other green feeds. This method of storing food has been around for centuries. However, modern day agriculture prefers to have these materials stored in a more efficient manner and this is why they are moving toward bunker silos or flat storage as opposed to tower storage.

As a result, these silos are not only easier to maintain, they also help farmers save time and money. For example, it is easier to transport a load of hay from the field to a bunker silo than from a tower silo.

These silos are also easy to build and don’t require any special masonry skills. This makes them cheaper than the older wood and stone structures.

They are also more durable and strong compared to the older silos. This is because they are constructed with masonry units that hook together, and the staves are reinforced by either flat or round metal bands.

When the masonry is sealed with a layer of concrete, it creates an airtight seal that prevents leakages from forming inside. This is important for the safety of the workers.

As a result, these silos are very effective in keeping the hay and other feeds fresh for longer periods of time. This is especially helpful for livestock producers. It helps to reduce the amount of waste produced by the animals. It also helps in preventing evaporation of the nutrients, which is an environmental problem.