HDI PCB: The Revolutionary Advanced Circuit Board Technology

Introduction:

Advanced Circuit Board Technology (ACBT) has made revolutionary breakthroughs in the field of electronics manufacturing. One such technological marvel is the High Density HDI PCB Interconnect Printed Circuit Board (HDI PCB). In this article, we will explore the manufacturing process, c Rigid-flex PCB haracteristics, advantages and applications of HDI PCB. We will also discuss how to choose the right HDI PCB for your specific needs.

Manufacturing Process:

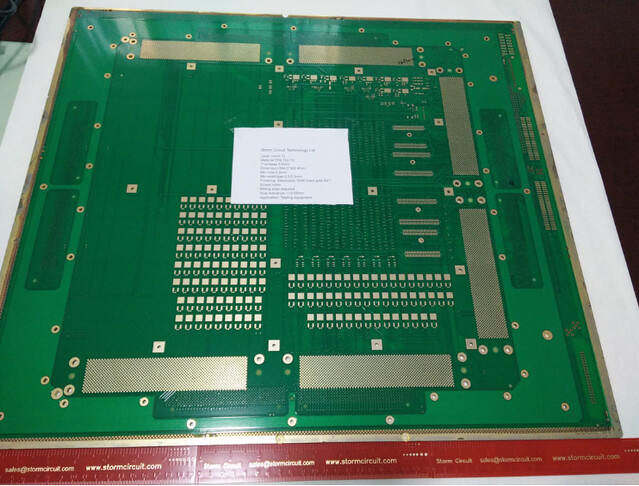

The production of HDI PCB involves a complex series of steps. It starts with the selection of high-quality materials like copper foil and special resin. These materials are laminated together at high temperatures and pressures to form a multi-layered substrate. The next step involves creating microvias using advanced laser drilling technology, allowing electrical connections between different layers within the bo High Density Interconnect PCB ard. Finally, a thin layer of solder mask is applied to protect and insulate the circuitry.

Characteristics:

HDI printed circuit boards offer several key characteristics that set them apart from traditional circuit boards. Firstly, their compact size allows for h HDI PCB igher component density, making them ideal for miniaturized electronic devices such as smartphones and wearable technology. Secondly, their intricate routing capability provides enhanced signal integrity and reduces electromagnetic interference (EMI).

Advantages:

The use of HDI PCB offers numerous advantages over conventional circuit boards. With its reduced size and weight, it enables smaller form factors in electronic devices without compromising performance or func HDI PCB tionality. Moreover, its highly efficient design improves thermal management while reducing power consumption.

Usage Method:

To effectively utilize HDI PCB in your electronic designs, it is important to consider certain factors during layout planning. First and foremost is understanding the required number of layers based on your device’s complexity and functionality demands. Additionally, careful consideration must be given to impedance control requiremen Rigid-flex PCB ts for critical signals.

How to Choose This Product?

When selecting an ideal HDI printed circuit board supplier or manufacturer,

there are several factors to consider. Firstly, ensure that the supplier has experience in high-density interconnect technology and possesses the necessary certifications for quality assu HDI PCB rance. Additionally, it is essential to evaluate their manufacturing capabilities and ability to meet your specific design requirements.

Conclusion:

In conclusion, HDI PCBs have revolutionized the world of electronics with their advanced circuit board technology. Their miniaturized size, intricate routing capability, and improved electrical performance m Microvia PCB ake them an ideal choice for various applications. By understanding the manufacturing process, chara HDI printed circuit board cteristics, advantages, usage methods, and selection criteria discussed in this article,

you can confidently incorporate HDI PCBs into your electronic designs and stay at the forefront of technological advancements.