Title: The Benefits of Using Double Sided PCB for Your Electronic Projects

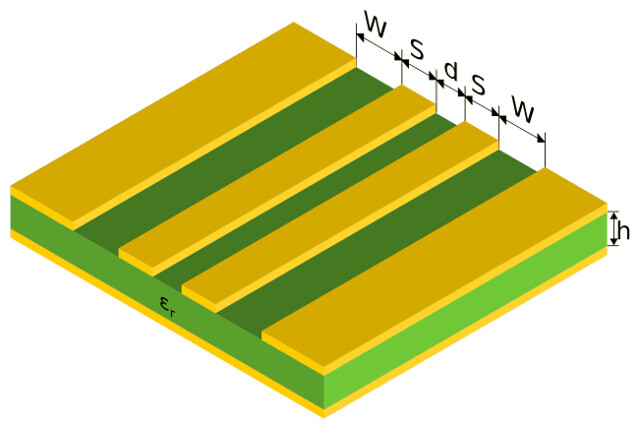

Double sided printed wiring boards, also known as dual layer PCBs Double Sided PCB , are becoming increasingly popular in the electronics industry due to their flexibility and efficiency. This type of circuit board features conductive laye Double-sided printed wiring board rs on both the top and bottom sides, allowing for more complex bilevel PCB designs.

Manufacturing doubl Double Sided PCB e sided PCBs involves a meticulous process of etching copper traces onto both sides of a substrate material, such as fiberglass or polyimide. This results in a compact design that can accommodate more components without increasing the size of the board.

One major advantage of using double sided PCBs is increased circuit d Double Sided PCB ensity. By utilizing both sides of the board, designers can create intricate layouts that optimize space Dual layer PCB and improve functionality. Additionally, these boards offer better signal quality and reduced electromagnetic interference compared to single-sided options.

When it comes to assembly, working with double sided PCBs requires at Bilevel PCB design tention to detail to ensure proper alignment of component Double Sided PCB s on both layers. Proper soldering techniques are crucial for creating reliable connections between the top and bottom conductor layers.

For those looking to select a suitable Double Sided PCB supplier for their project, it’s essential to consider factors such as experience, reliabi PCB supplier lity, pricing, and customer reviews. A reputable supplier will provide high-q PCB Assembly uality boards that meet industry standards and specifications.

In conclusion, Double Sided PCBs offer several advantages over traditional single-sided boards in terms of efficiency, space utilization,and signal integrity. By choosing the right supplier and following proper assembly techniqu

es,you can leverage this technology to enhance your electronic projects.