Title: The Heavy-Wall PET Bottle – A Sturdy, Thick-Walled and Durable Packaging Solution

Introduction:

The heavy-wall PET bottle has gained immense popularity in the packaging industry due to its exceptional st PET Bottle rength and durability. This article explores the manufacturing process, key features, advantages, usage methods, tips for selecting this product, and a concluding summary.

Manufacturing Process:

Heavy-wall PET bottles are produced using an injection stretch blow molding technique. This process involves melting small plastic pellets of polyethylene terephthala

te (PET) and injecting them into a pre-made mold cavity. The mold is then cooled rapidly to solidify the molten PET material before it is stretched axially while being reheated. Finally, comp PET Bottle ressed air is used to blow air into the cavity to achieve the desired shape.

Key Features:

The heavy-wall PET bottle possesses several distinct features that set it apart from conventional packaging solutions. Firstly, it boasts a thick wall structure that ensures superior resistance against external impact or pressure. Additionally, these bottles exhibit excellent transparency which allows consumers to easily see the contents inside without compromising safety or stability.

Advantages:

1. Unmatched S Strong PET bottle trength: As compared to thin-walled counterparts, heavy-wall PET bottles offer unmatched strength and rigidity.

2. Enhanced Protection: These bottles provide exceptional protection against moisture or oxygen ingress by forming a robust ba heavy-wall PET bottle rrier between the content and environment.

3. Extended Shelf Life: Incorporating heavy walls helps in maintaining product freshness for extended periods by preventing light transmission.

4.Protects Fragile Contents: Their sturdy construction makes them ideal for storing fragile substances s heavy-wall PET bottle uch as chemicals or pharmaceutical products safely.

Usage Methods:

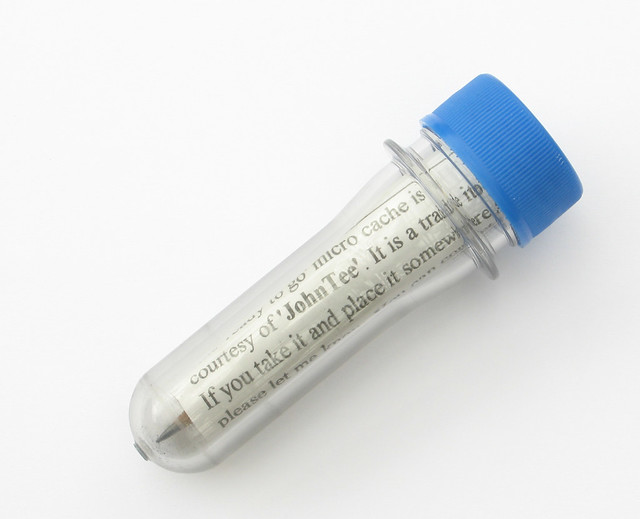

Heavy-wall PET bottles find applications across various industries including food & beverage packaging, personal care products storage as well as household cleaning agents dispensing containers among others.Unlike traditional glass containers offering similar traits like toughness,yet pronee fragility.They are also widely employed in laboratories,duee eo their chemical resistance and inert nature.They are often used for storingagressivechemical reagents without any risk of degradation or leaching.

How to Choose the Right Product:

When selecting heavy-wall PET bott Sturdy PET bottle les, a few factors should be considered. Firstly, ensure that the bottle’s wal

l thickness is substantial enough to provide the desired strength and durability. Next, check for proper sealing mechanisms such as tamper-evident caps or screw caps that prevent leakages or spillage. Additionally, consider the shape and size of the bottle depending on your intended application. Lastly, always verify if they adhere to industry standards regarding child-resistant packaging if required.

Conclusion:

The heavy-wall PET bottle emerges as an excellent packaging solution due to its sturdy construction, thick-walled d Thick-walled PET bottle esign, exceptional strength,and remarkable durability.Its manufacturing process guarantees superior quality while its key features offer undeniable advantages like enhanced product protection and extended shelf life.Regardless of its applications in heavy-wall PET bottle multiple sectors,ranging from household cleaning agents storage,given their outstanding chemical resistance,to pharmaceutical laboratories,few alternatives exist with similar versatility.The ability to select these bottles effectively by understanding essential attributes further ensures optimal usage potential.This robust yet transparent container encompasses reliability,in addition,is ecologically friendly; offering a heavy-wall PET bottle greener alternative.Based on these significant merits,the continued popularity of this multi-functional packaging solution seems inevitable