Title: The Ultimate Guide to Waterproof Crimp Connectors

Water-resistant wire connectors, Damp-proof wire splices, Marine-grade crimp connections, Moisture-resistant crimp connectors, and Liquid-tight wire terminations are essential waterproof crimp connectors components in various electrical applica waterproof crimp connectors tions. Among these options, waterproof crimp connectors offer unparalleled protection against moisture and water infiltration. As a leading waterproof connector manufacturer, we take pride in providing high-quality landscape wire connectors that are both durable and reliable.

Manufacturing Process:

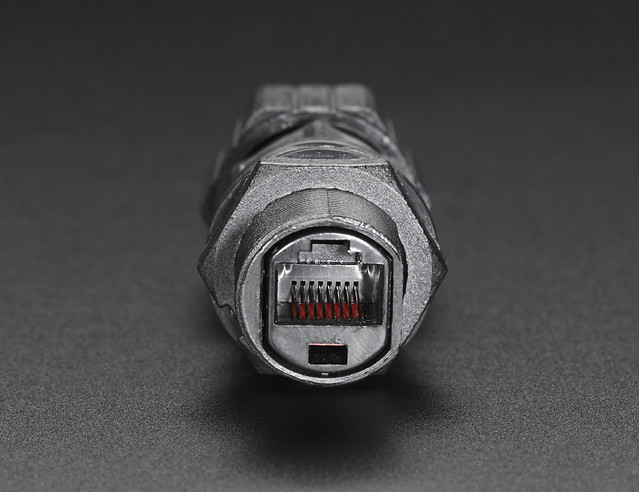

Waterproof crimp connectors are typically made from ma

terials such as nylon or polypropylene that have excellent resistance to water and corrosion. The wires are first stripped of insulation before being inserted into the connector housing. A specialized crimping tool is then used to secure the connection by compressing the metal sleeve onto the Marine-grade crimp connections wires.

Features:

– Watertight seal prevents water damage

– Corrosion-resistant for increased longevity

– Easy to install with proper tools

– Suitable for outdoor use in various weather conditions

Advantages:

One of waterproof connectors the key advantages of waterproof crimp connectors is their ability to maintain a strong connection even when exposed to moisture or submerged in water. This makes them ideal for marine environments, outdoor lighting installations, and underground wiring applications where traditional connectors may fail due to moisture ingress. waterproof crimp connectors

Usage Instructions:

To ensure a proper connection with waterproof crimp connectors, follow these steps:

1. Strip insulation from wires according to manufacturer guidelines.

2. Insert stripped wires into connector housing.

3. Use a landscape wire connectors waterproof crimping tool to secure the metal sleeve onto the wires.

4. Test the connection for tightness and conductivity before sealing it.

How to Select the Right Product waterproof connector manufacturer :

When choosing waterproof crimp connectors for your application, consider factors such as wire gauge compatibility, environmental conditions (e.g., exposure to saltwater or UV radiation), and installation method (e.g., Water-resistant wire connectors above ground or buried). Consulting with a knowledgeable supplier can help you find the best solution for your specific needs.

Conclusion:

In conclusion, waterproof crimp connectors are indispensable components for ensuring reliable electrical connections in wet or damp environments. By investing in quality products from reputable manufacturers like us,

you can safeguard your Damp-proof wire splices electrical systems against water damage and enjoy peace of mind knowing that your connections will remain secure under any conditions.”