Waterproof Ethernet Connectors: Making Connections Safe and Secure

Manufacturing Process:

One of the most critical components in any network infrastructure is the Ethernet connector. In recent years, there has been an increasing demand for waterproof Ethernet connectors due to thei waterproof connector manufacturer r ability to withstand harsh environmental conditions. These connectors are manufactured using advanced techniques that involve sealing them against moisture and ens

uring maximum durability.

Features:

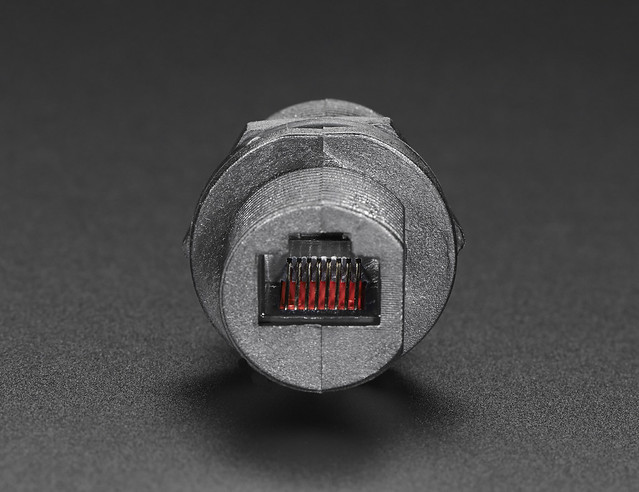

The Waterproofed Ethernet connector, also known as a Moisture-proof or Sealed Ethernet connector, offers numerous features that make it an ideal choice for various applications. Firstly, these connectors have a robust construction with high-quality materials that provide excellent resistance against water ingress. This ensures reliable performance even in demanding environments.

Additionally, these connectors are designed to meet rigorous standards for IP (Ingress Protection) ratings such waterproof ethernet connector as IP67 or IP68. They offer complete protection against dust particles and immersion in water beyond 1 meter depth for extended periods.

Advantages:

One of the significant advantages of Waterproofed Ethernet connectors is their ability to prevent Sealed Ethernet connector damage caused by exposure to moisture or water intrusion. By using specially designed seals and gaskets, they create a watertight connection between cables without compromising on signal integrity.

Moreover, these connectors ensure long-term reliability by safeguarding delicate components from corrosion and rusting due to prolonged exposure to humid conditions. This feature makes them indispensable in outdoor insta Moisture-proof Ethernet connector llations where networking equipment must endure varying weather conditions.

Usage Methods:

Using waterproof ethernet connectors is straightforward and similar to regular non-waterproof variants. First, strip the cable ends carefully while maintaining proper insulation lengths specified by manufacturers’ guidelines.

Next, identify which type of connector suits your specific needs—be it RJ-45 or M8/M12 style—to establish compatibility with corresponding port configurations available on networking devices efficiently.

Once identified,

simply align pins Waterproofed Ethernet connector /grooves correctly when plugging into ports,

ensuring full insertion until you hear/feel click indicating secure attachment.

Repeat this process each end, ensuring cables firmly plugged before routing/installing as required.

How to Choose Waterproof Ethernet Connectors:

When selecting waterproof Ethernet connectors for your application, several factors waterproof ethernet connector should be considered. Firstly, it’s crucial to identify the IP rating requirement based on the installation environment and level of protection desired. Additionally,

confirm compatibility/connectivity requirements (e.g. waterproof low voltage wire connectors , RJ-45 or M8/M12),

confirm durability expectations in terms of mating cycles or pull force ratings,

and choose suitable sizes/form-factors depending on cable thickness/OD & available space.

Conclusion:

In conclusion, waterproof Ethernet connectors play a vital role in safeguarding network connections from environmental hazards like water and moisture. Their robust construction, reliable performance, and ability to withstand harsh conditions make them indispensable for various applications such as outdoor installations and industrial settings.

By adhering to proper usage methods and considering key selection criteria like IP rating and waterproof ethernet connector form-factor compatibility, one can ensure optimal performance while maintaining efficient data transmission over extended periods.

With their exceptional versatility and reliability, Waterproofed Ethernet connectors have emerged as the go-to solution for engineers seeking durable network connections that meet industry standards whi 12 volt 2 pin waterproof connector le protecting sensitive equipment against adverse environmental factors.