Why Choose V-Groove?

Tongue and groove is a method of fitting similar objects together, edge to edge, used mainly with wood, flooring, parquetry, panelling, and similar constructions.

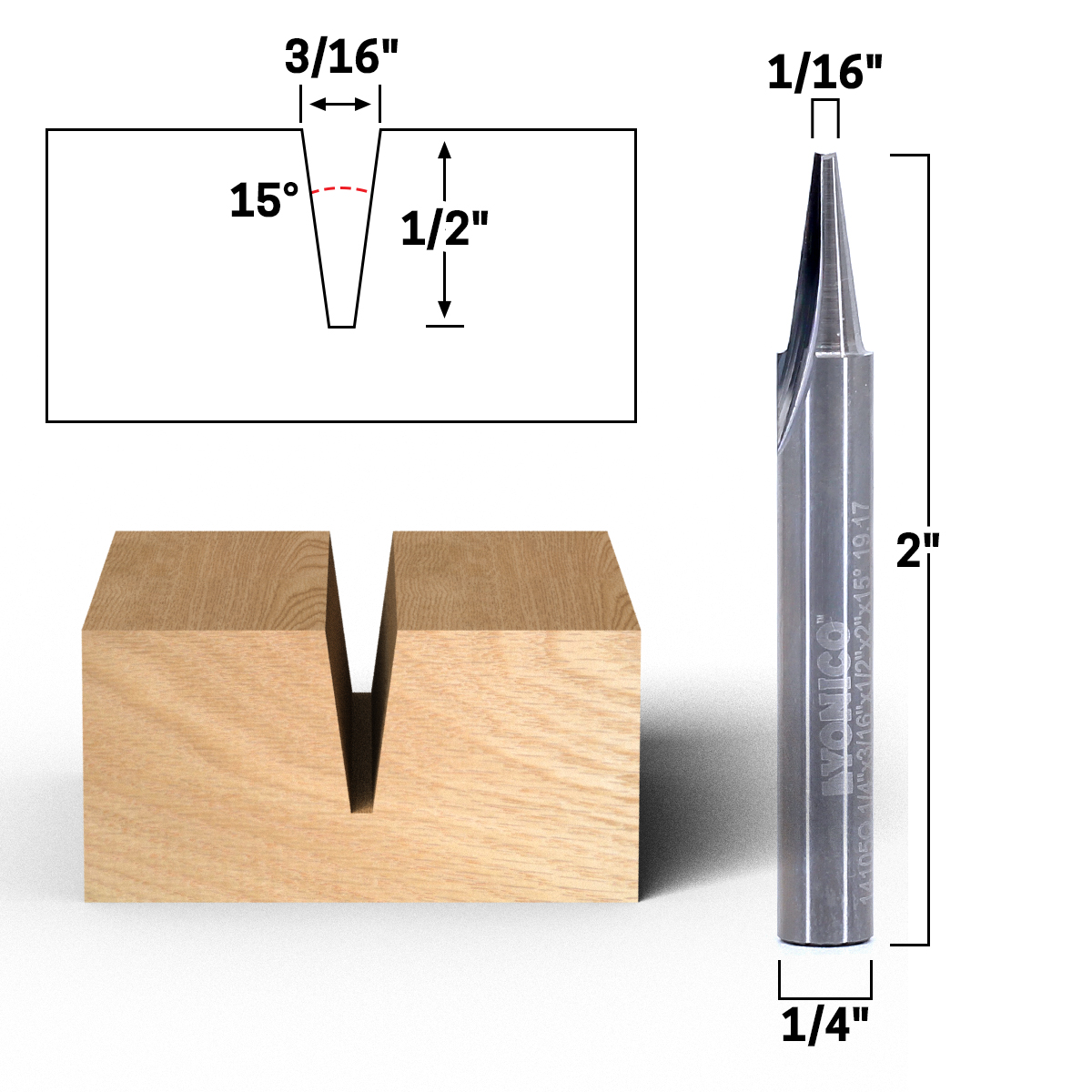

V-Groove machining is a cutting technique that uses a cutter head to make a precise V-shaped groove on a sheet of material.

The groove helps the material resist cracking and tearing when it’s installed in a joint. It also enables the use of joint filler.

Durability

Regardless of what material you’re bending, the durability of V-groove makes it an ideal way to do the job. It’s also a good choice for applications that require quick, high-quality work, such as building remodeling or furniture making.

For example, in jet engine designs, v-grooves are used to create air seals between the fan case and nacelle. The grooves need to be durable, able to withstand repeated impacts and corrosion over the life of the vehicle. They need to be easy to maintain in the field and resist abrasion.

Another application is in structural engineering, where a v-groove may be cut into a crack to help fill it. This allows joint filler to be applied without risk of sag and helps to stabilize the crack.

In interior design, v-groove can be used to create a variety of decorative effects on different materials. It can be used to create picture frames, window awnings and wall panels.

It can also be used to provide a more seamless look to metals, such as cladding panels and trims. For this reason, it’s often used on the exterior of buildings and in places that are exposed to severe weather conditions.

For this reason, it’s typically best to use a thicker grade of stainless steel or other material for v-grooved projects. Thinner grades of metal can be more difficult to bend and are likely to result in wastage during the forming process.

If you need a v-groove, consider using PVD coloured stainless steel or other materials that are resistant to wear and corrosion. This will ensure that the finished project will last longer and be less expensive to repair.

A V-groove can be created by a machine that cuts and folds the metal. This enables it to mimic solid bar material at around a tenth of the cost and avoids wastage.

You can use a v-groove to make a wide range of shapes, including angles and corners. It can be used in many industries and is available for both ferrous and nonferrous materials, as well as composites.

The v-groove can be cut to the required thickness and then bent at the press brake. It can be completed with a machine or v-groove by hand. This process can be slow and expensive, but it’s worth the effort to produce a professional-looking product with minimal waste.

Style

Whether you are a DIYer or a design professional, v-groove is an exciting style of wood cladding that can add drama and character to any space. It is also one of the most affordable options.

This type of cladding is used on walls and ceilings to add a natural touch to any room. It can be applied horizontally or vertically and comes in a variety of styles, including rustic, traditional, and contemporary.

It is a popular option for many homeowners because it is affordable and easy to install. It is also lightweight and durable.

The best thing about this style of cladding is that it can be customized to fit your space perfectly. You can choose the width, color, and finish of your v-groove panels to make them fit in with your design goals.

You can even stain your v-groove panel to make it more unique and to enhance its beauty. This is a great way to show off your personal style.

Another popular cladding style is shiplap. Like v-groove, shiplap has a tongue and groove joint that links the boards together. However, it has a broader face than v-groove. This means that it can be set apart from each other, giving each wall a different look.

As a result, it is an excellent choice for modern homes that need a more updated look and feel. It can also be used in older homes to provide a timeless style.

Unlike other cladding styles, shiplap can be painted or stained to match the color of your room. This makes it a great choice for any space that needs to be updated without sacrificing its charm.

Other cladding styles, such as beadboard and V-groove, can also be painted to suit your style and your home’s personality. They are both affordable and easy to install, making them ideal for most any project.

Easy to install

A v-groove board is an easy way to add character and style to your porch. It is a quick and economical upgrade that can be installed in a weekend.

You can use v-groove boards for both ceiling and walls, depending on how you want them to run. Typically, you will install them perpendicular to the wall framing, but you can also choose to change the direction of the boards by installing 1×2 battens along each row.

In addition to the ease of installation, v-groove is affordable and comes in a variety of colors and finishes. This makes it a popular option for both commercial and residential construction.

Unlike shiplap, which has a curved edge that overlaps with its adjacent pieces, v-groove offers a flatter cladding surface. This creates less overlap between pieces and can help with water resistance.

V-groove is often used in wood siding, as it can mimic the look of traditional wood siding without the water damage. This siding panel can be installed in a wide range of exterior and interior applications, including kitchens and bathrooms.

Before you begin installing v-groove, make sure you have all the tools necessary for the job. This includes a nail gun, two-inch nails and a brad nailer. You will also need a hammer and a drill.

You will also need to plan each row of tongue-and-groove before you start putting up the boards. This will help you determine the length of each row and the number of rows needed. It will also make it easier to cut the boards to fit.

Once you’ve determined the length of each row, mark the boards to cut. For each row, cut them so they’re 1/4 inch shorter than the floor-to-ceiling height. This will help ensure that the rows are straight and that they don’t fall over framing members.

Another way to make the v-groove board easier to install is by adding a 45-degree chamfer on each end of each board. This will mask any small inconsistencies in the butt joints of the boards.

This will help you get v-groove the look you desire without having to worry about a sloppy installation. This is especially important if you’re using wood over drywall or plaster.

Affordable

Affordability is an issue for many homeowners, especially those with tight budgets. Luckily, there are some affordable options out there. One of the most popular is v-groove, which offers a wide variety of woods and finishes in a variety of sizes. The best part is that it is not only cost effective, but also very pleasing to the eye.

V-groove is usually paired with a premium grade tongue and groove paneling in your choice of a variety of wood species and colors. Our high quality tongue and groove panels can be made from any type of wood, including premium grade eastern white pine, which is light and natural. It can also be stained to complement your home decor.

The v-groove is also commonly used during metal fabrication to produce the fanciest bends in sheet metal. There are a variety of machines and blades to choose from, as well as different types of materials that can be v-cut. The aforementioned v-groove entails a machining operation that is often times more costly than traditional hand tools, but which is worth the hefty price tag. The aforementioned milling procedure can be used to make a range of items from picture frames to trays and boxes.